Understanding [everything] is fundamental to making things better.

If we worked on the assumption that what is accepted as true really is true, then there would be little hope for advance.

— Orville and Wilbur Wright

How We Work

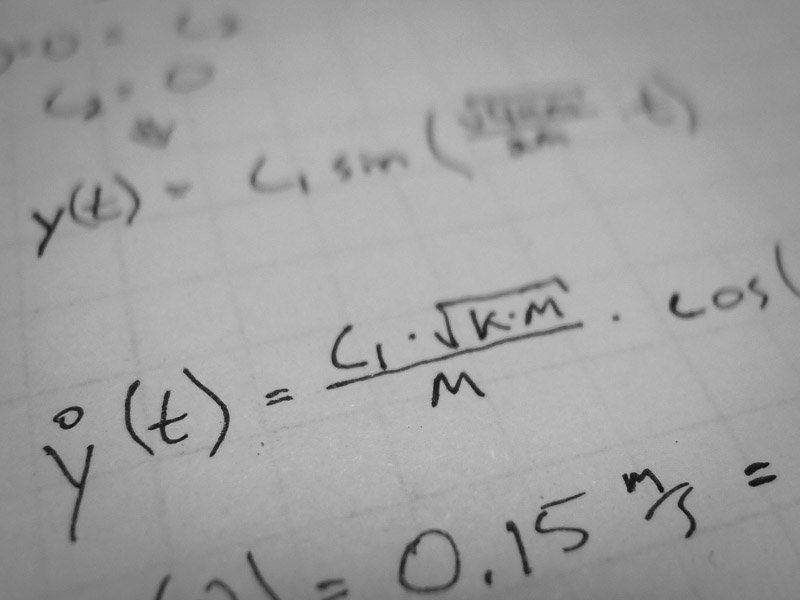

The difference between creating breakthrough-technology and making iterative-technological improvements comes down to a different way of thinking. As simple as it may sound, understanding the nuance of “how” something works is at the core of our approach in any project.

This doesn’t just apply to the technology around your IP, but every step in the Product Development process, from mitigating risk in early stages of development to shaping product design to fit within and selectively push the limitations of technology and manufacturing methods of today.

We practice this in many ways, from close collaboration with all team members to methodical prototyping and testing. One example of this is how we often have our 3D printers running overnight creating physical parts we can review the next morning to help us validate work and iterate designs effectively.

What We Practice

Knowledge can expand or limit imaginations - we chose the former.

What some see as guardrails, we see as building blocks to the next level. We aren’t afraid to ask questions to develop a solid understanding of anatomy, technology or process to empower designs and push the right boundaries.

Our decades of combined experience in Product Development enable us to efficiently tap into the knowledge of your team, extract key information from industry experts, bridge the gap between disciplines, and envision how to take ideas to the finish line.

What We Understand

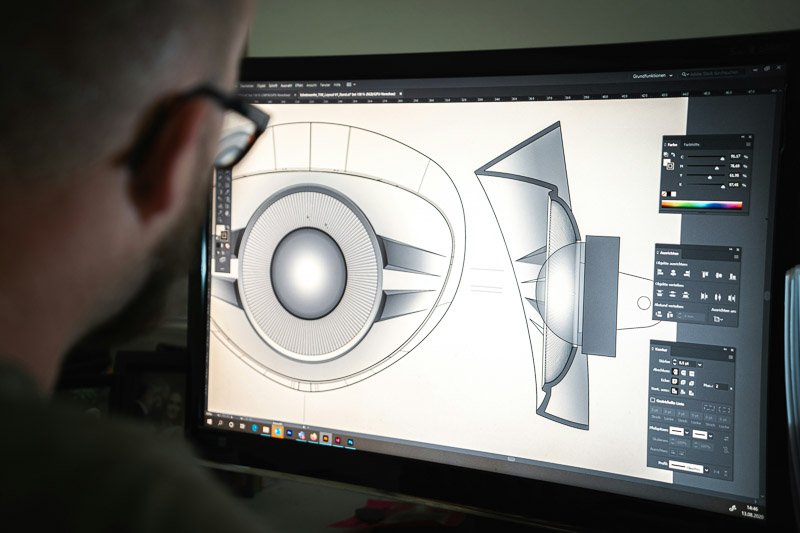

Design & User Experience

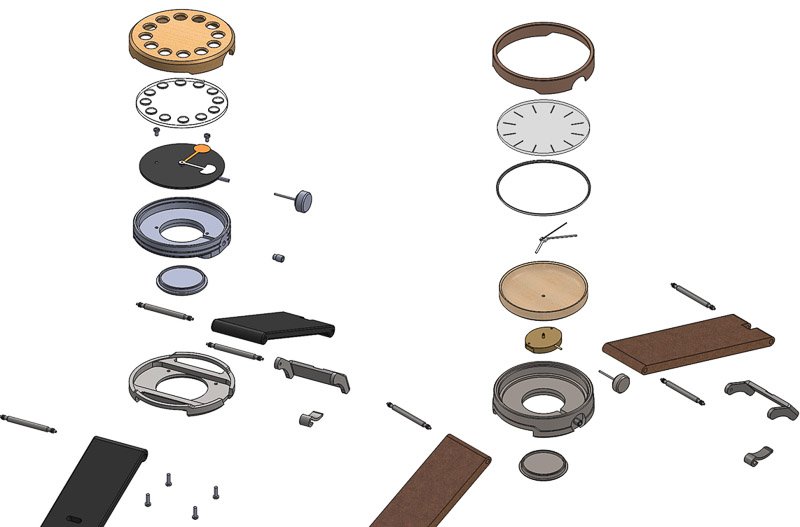

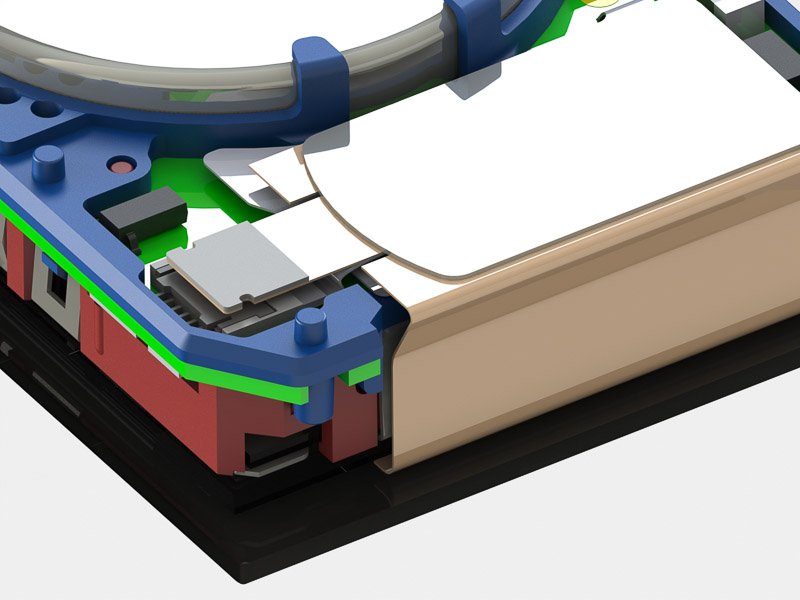

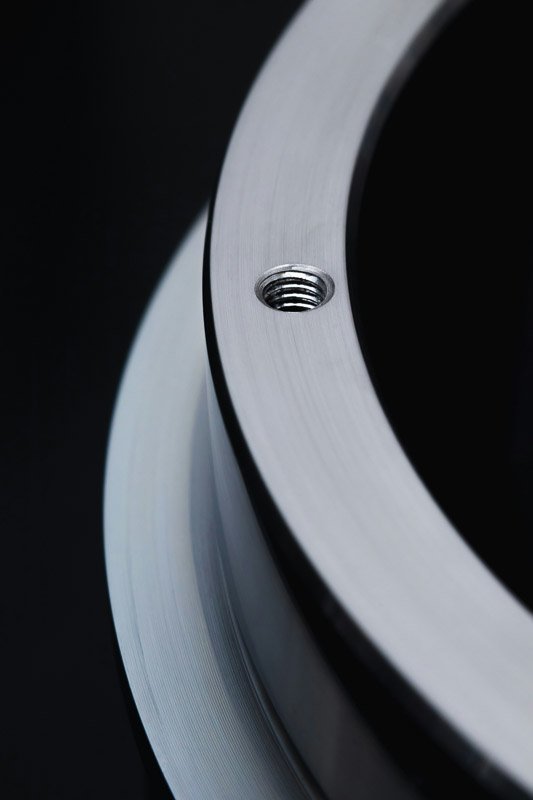

Work closely with Industrial Designers, Engineers and Manufacturing Partners throughout the development process to maintain design intent and bring the best possible product to market for everyone involved. Balancing Form & Function leaves nothing arbitrary. The aesthetics, user experience, & manufacturing stay at the forefront of our process.

Our attention to detail & consideration of the final vision is built into every sketch.

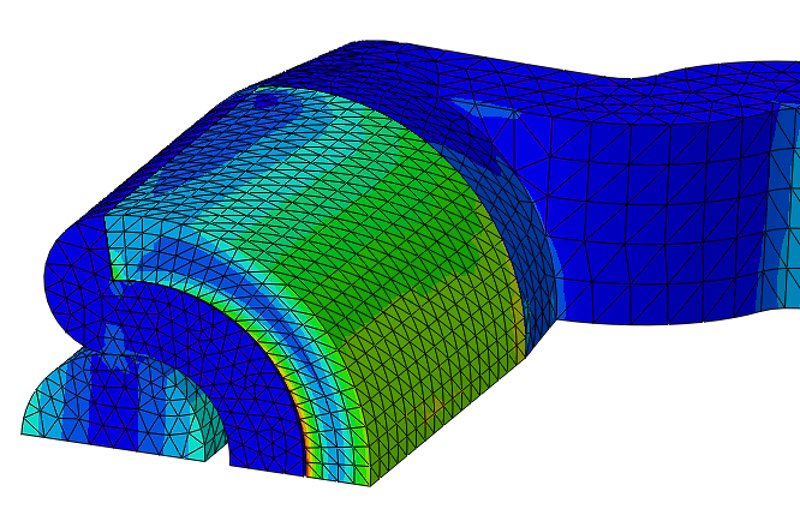

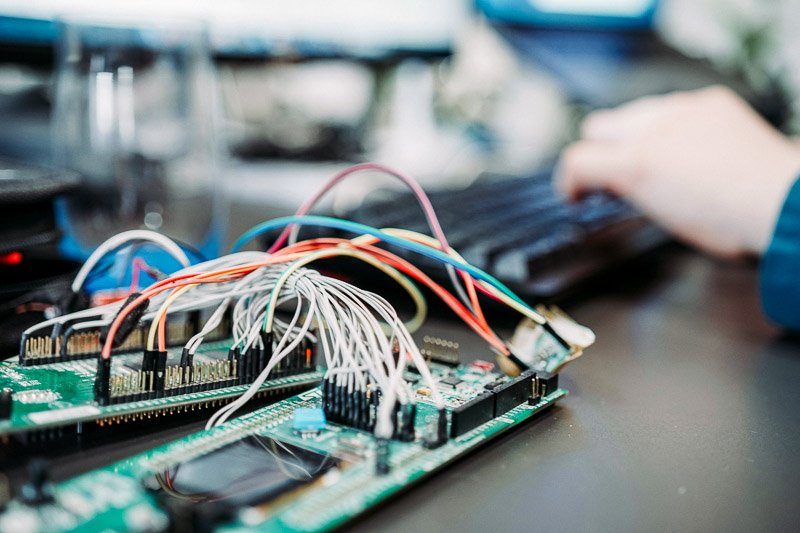

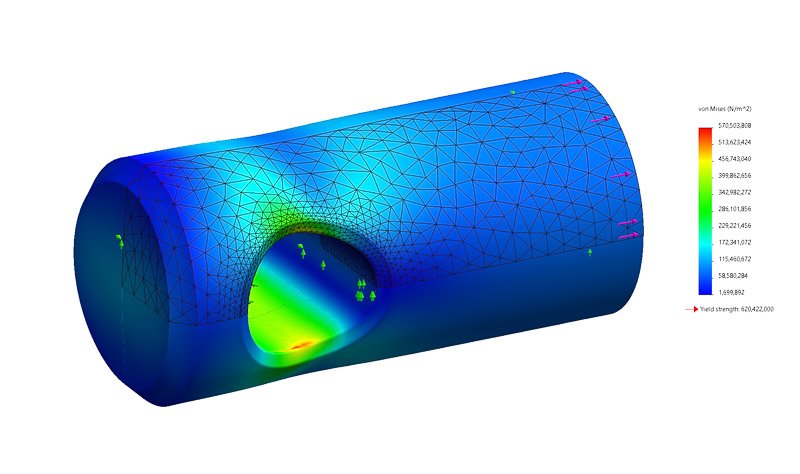

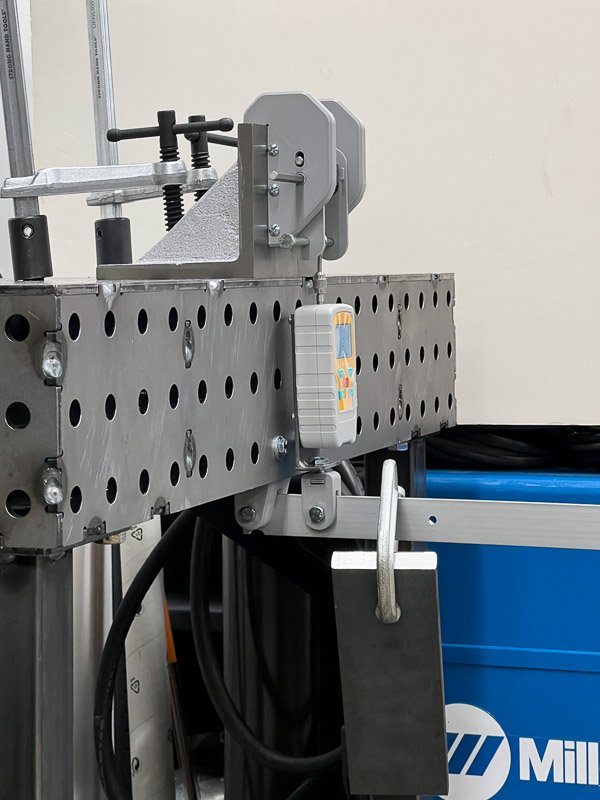

Engineering, Testing & Analysis

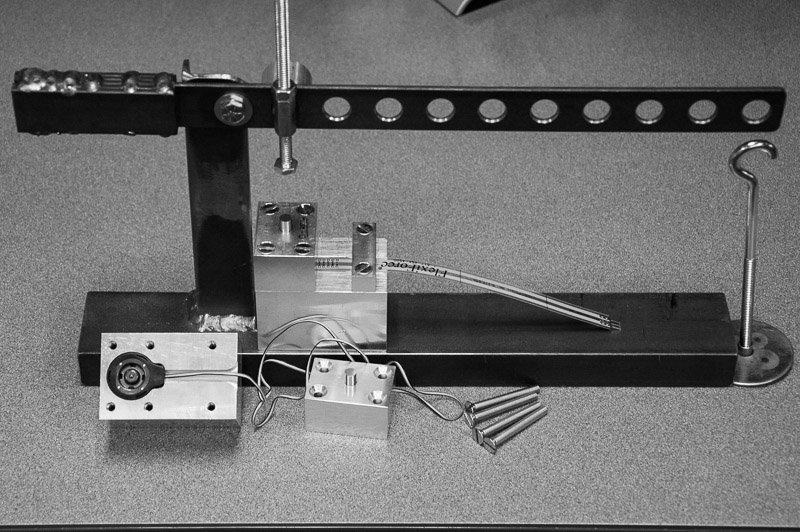

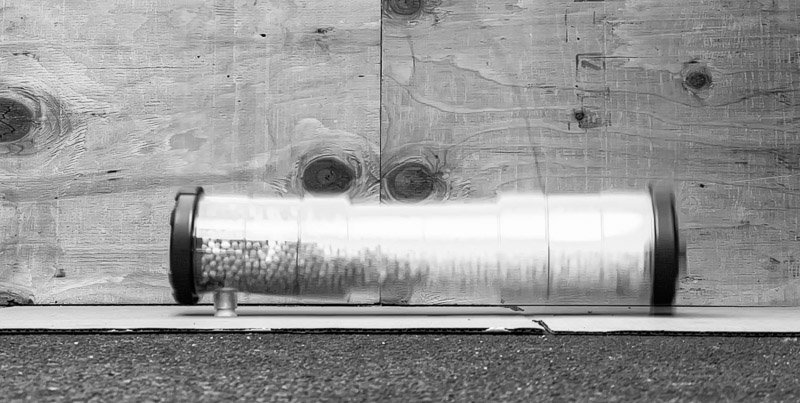

Hands-on prototyping, testing and diagnostics sharpens our engineering decisions throughout projects and reduces risk later on. Some of our tools, processes and capabilities include:

3D CAD modeling and surfacing, 2D Drawings, Finite Element Analysis (FEA), 3D Printing, Prototyping, Performance Testing (Wear, Impact, Drop, Fatigue, Deflection, Ingress Protection (IP), Flow, Environmental, Material, Tensile, Compression, etc), Failure Analysis, Diagnostics, 3D Scanning, and more.

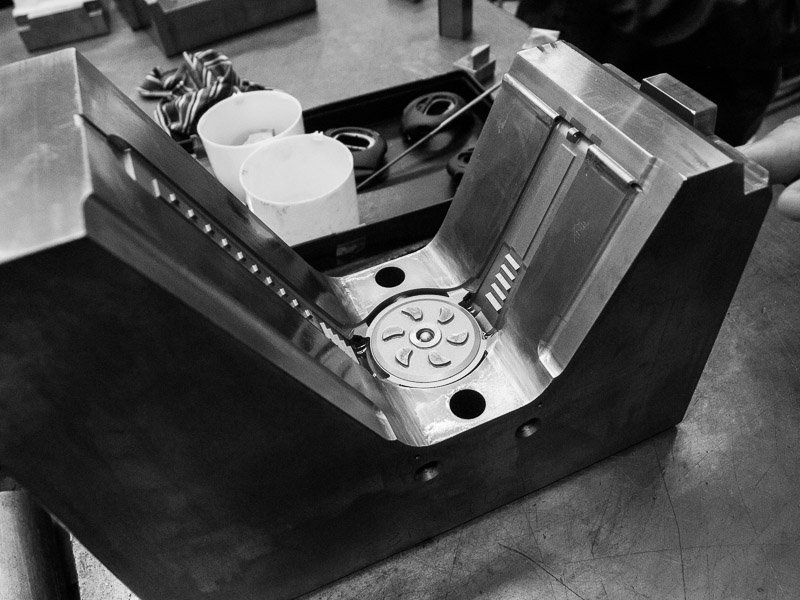

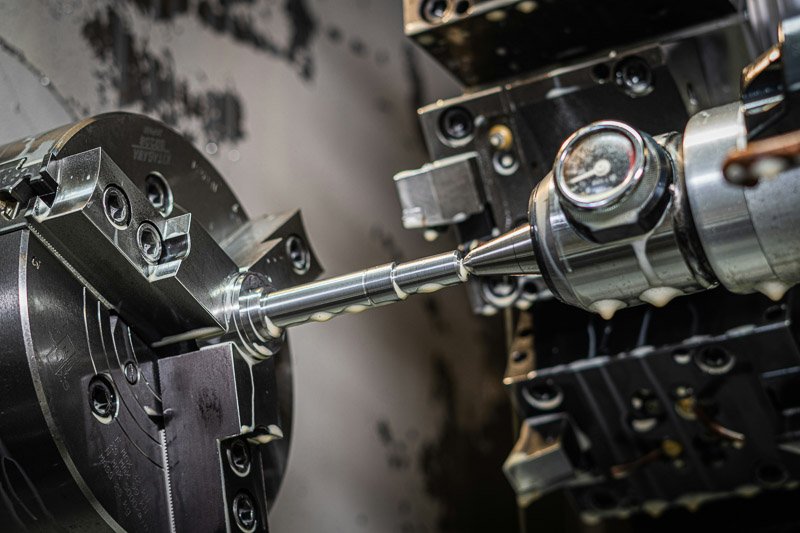

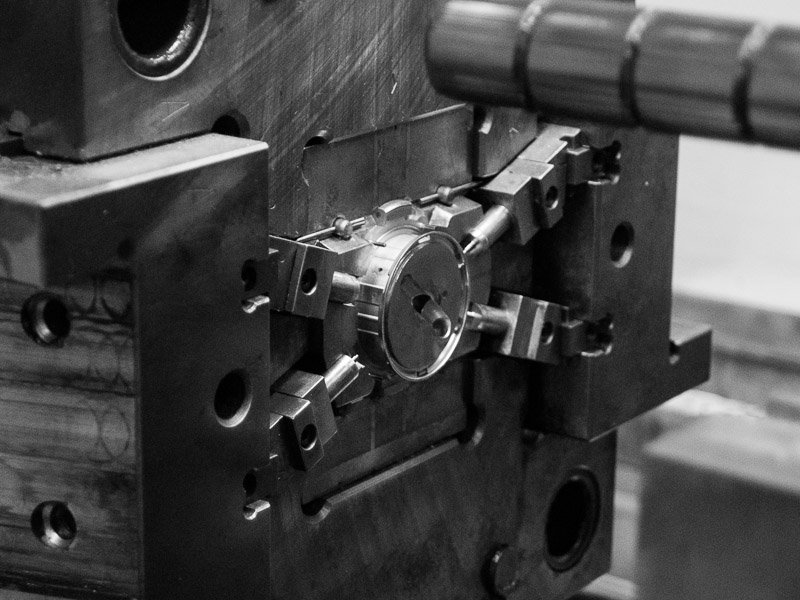

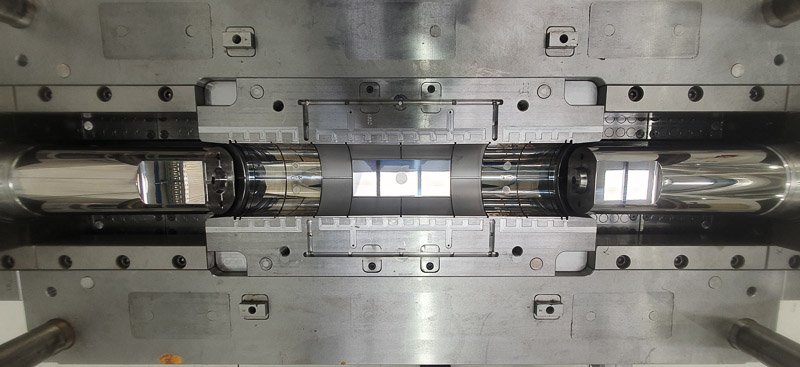

Design for Manufacturing (DFM)

DFM is considered from the first sketch and PDS to ensure ideas have a path into production. Some of the many manufacturing methods we have experience with include:

Polymer Injection Molding, Plastic Rotational Molding, Plastic Extrusion, Aluminum Extrusion, CNC Milling, Turning, Swiss Turning, Laser Cutting, Waterjet Cutting, Forming, Stamping, Welding, Brazing, Routing, Converting, Laminating, Lost Wax Casting, Die-Casting, Chemical Etching, Mechanical Finishing, Anodizing, Black Oxide, Plating, Assembly, Quality Assessment, CMM, Manufacturing Drawings, Packaging, Contract Manufacturing, and more.

Let’s redefine what’s possible. Together.

Steven is a creative problem solver and not afraid to offer up solutions to problems we didn't even know we had. His ability to see beyond his current task and into the overall goals of the current project are an incredible asset.

— Andrew Greenberg | CTO @ APDM